Which Foredom motor is right for me?

Here we are going to focus on the Hang-up or Bench mounted motors. Sometimes these are referred to as a Flexshaft, Rotary Tool, Pendant Motor, Dremel, or even Drill motor. There are also micro-motors available, we will chat about them in another post.

There are three Foredom motors available in 230V (so suitable for us in the UK and most of Europe); the SR, the LX, and the PG motor

Most people should choose the SR motor, this is the “standard” Foredom motor. I will explain the differences between the motors in detail further down.

For clarity, there is also a TX motor, this is only available in 115V (US voltage) so you would need a converter. We carry this motor, but most people will do better with one of the other motors.

FLEXSHAFT TYPES

Here at Metal Clay Ltd we have chosen to mainly carry the “Keytip” version of the Foredom SR and LX motors. Key tip refers to the type of flexshaft that is attached to the motor. It can be confusing as many refer to their Foredom motor just as their “flexshaft” (I know, I do!) but the flexshaft is in fact specifically the black cable which connects your handpiece with the motor.

Foredom have three types of flexshaft; keytip, square drive, and slip joint – the main difference is what the end or tip of the flexshaft looks like.

For a jeweller (and most other users!), the keytip version would be my choice as it gives you the most flexibility with 17 different handpieces available to choose from.

The slip joint (sometimes called European connection), choosing this means you are limited to only 7

handpieces.

The square drive would be the right choice if you are doing REALLY heavy-duty large work (like Foredom say, if you “carve totem poles“). You are limited to only 4 handpieces that fit the Square drive flexshaft type.

Our recommendation; if you are jewellery maker and want the flexibility to use any of all the fabulous Foredom handpieces, choose the keytip style flex shaft.

SO – WHICH MOTOR SHOULD I CHOOSE?

How will you use your Foredom flexshaft motor?

Do you need an all-rounder that works for anything you throw at it? Are you a professional who do the same task over and over, and need a machine that is specifically for that, say, stone setting, or carving heavy hardwood?

What you use it for should guide you in your motor choice. It should also affect your choice of speed control (do you want a foot pedal, or a dial control on your desk?), and of course, what hand piece you get.

Also, do you want a hanging motor, or one that is sitting on your desk?

Let’s look at the motors first, and then we will talk about speed control and handpieces.

The motor is the part that drives the flexshaft. It is important that the flexshaft isn’t curved too tightly when you use it. Inside the sheath the shaft is spinning (fast) to drive your handpiece. If you bend it too much, it will put a lot of pressure on the shaft, which can cause it to break. This is why a hanging motor is usually the best choice for most makers.

A hang-up (also called pendant) motor is placed on a motor-hanger hook (which is clamped to your desk or fitted to your wall).

You can also get a desk motor, mounted on a heavy base which stand direct on your desk. A desk-mounted motor would need to be placed at a little distance from where you work, so you can use it with a relatively straight flexshaft. And, if you’re like me and work with a cluttered table/desk, that isn’t ideal…

A hanging motor is the first choice for jewellery makers, and for general craft applications. If your work is very large, like furniture which you stand on the floor to work on, a desk mounted motor might be a better fit for you.

SR MOTOR

80% of our customers should get an SR. This is the most popular motor with the plenty of power and the speed needed for most jobs, without stalling or slowing down while under normal load.

80% of our customers should get an SR. This is the most popular motor with the plenty of power and the speed needed for most jobs, without stalling or slowing down while under normal load.

It can run in both forward and reverse. Running in reverse is valuable for symmetrical grinding and carving, to help some abrasives live longer, and if you’re left handed, using the reverse mode can give you more control over your tool.

- 1/6* HP

- Fast – speeds up to 18,000 RPM.

- Run in both forward and reverse – handy for symmetry, releasing stuck drills, left-hand users, and maximising the lifespan of many rotary accessories.

- Universal ball bearing motor.

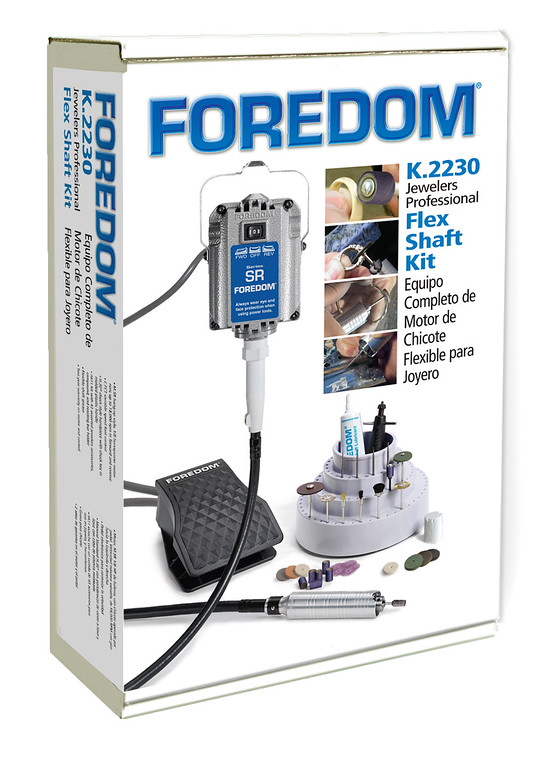

Our recommendation for a general jewellery maker is to choose the hanging style SR motor (with a keytip flexshaft). A great kit to give you the most flexibility is the SR Complete Jeweller’s Kit with H.30 Handpiece. This comes with the H.30 handpiece, a great all-rounder handpiece. The H.30 has an adjustable chuck, this means you can use any size bur, drill, or other accessory bit, up to 4mm thick.

If you specialise in stone setting or engraving, and this is the main reason for getting a Foredom – keep reading.

LX MOTOR

The LX motor is a more specialised motor. The 1/10HP LX motor is slow but strong, it is Foredom’s most powerful motor. It has full strength from the start at 500RPM, all the way to the max speed. It is designed for drilling, wax modelling, stone setting, chisel carving, and other slow speed applications.

The LX motor is a more specialised motor. The 1/10HP LX motor is slow but strong, it is Foredom’s most powerful motor. It has full strength from the start at 500RPM, all the way to the max speed. It is designed for drilling, wax modelling, stone setting, chisel carving, and other slow speed applications.

- 1/10HP*

- Strong – the most powerful of all Foredom motors at low speeds.

- Max speed 5,000 RPM. So it is slow compared to the SR, it runs at less than a third of the speed. This is good when using a Hammer or Carving hand piece (like the H.15 and H.50) which can be damaged at higher speed.

- There is no reverse rotation on this motor, it runs in forward only.

- Permanent magnet motor.

PG POWER GRAVER MOTOR KIT

The Foredom PG PowerGraver is an even more specialised motor, it comes in one complete kit only. It is a dedicated power assisted stone setting and engraving system, with a specialised reciprocating handpiece (which feels quite a bit like a traditional hand engraving tool). It is used for engraving and decorative work. If you’re a stone setter use it to shape bezels, turn prongs, cut grooves and channels. You can adjust the impact force to suit what you are doing.

The Foredom PG PowerGraver is an even more specialised motor, it comes in one complete kit only. It is a dedicated power assisted stone setting and engraving system, with a specialised reciprocating handpiece (which feels quite a bit like a traditional hand engraving tool). It is used for engraving and decorative work. If you’re a stone setter use it to shape bezels, turn prongs, cut grooves and channels. You can adjust the impact force to suit what you are doing.

- 1/20HP*

- High torque and low speed for specialised applications

- Max speed 2,800 RPM.

- There is no reverse rotation on this motor, it runs in forward only.

- Permanent magnet motor.

- Comes with the H.9D handpiece with an adjustable impact force

- A dial control adjust the speed up to 2,800RPM, and a foot pedal turn the motor on and off.

- Included in the kit is a set of different gravers

*The horsepower of Foredom motors is rated at continuous duty or maximum efficiency under load, not maximum output. Other manufacturers list maximum output, which is not a realistic measure of horsepower during actual use. The maximum output of Foredom motors is higher than what is listed.